10 Layer Impedance Control PCB Multilayer PCB Manufacturing

Product Description

Keywords: 10 Layer Impedance Control PCB, Multilayer PCB Manufacturing servics, 10 Layer Impedance Control PCB Manufacturing

Production process requirements

Material: FR4 TG150

Layer Count: 10 Layers

Board Thickness: 1.6mm

Copper Thickness: 1 Oz

Min. Hole Size: 0.2mm

Min. Line Width: 0.10mm

Min. Line Spacing: 0.10mm

Minimum Drill Size: 0.10mm

Minimum Trace & Gap: 0.10mm

Surface Finishing: Immersion Gold

Solder mask Color: Customized

Delivery Time: 3 - 15 days

Certification: UL, TS16949, ISO-9001, and RoHS

Packaging Details: Vacuum Packing and High Quality Carton Box

Minimum Order Quantity: 1 Piece

Impedance Control PCB Manufacturer

Jinghongyi PCB provides you with 10 layers of high-precision impedance control PCB manufacturing services. Here you can get real-time quotations, our production process, PCB board material, delivery cycle and so on.

You may have the same questions:

Q: there are so many 10 layer PCB manufacturers. What are your advantages?

A: We are a professional PCB manufacturer and assembler. We are specialized in manufacturing high-precision 10 layer PCB with fast delivery time. The prototype manufacturing of double-sided PCB can be delivered within 24 hours. And we have our own test stand factory. The price of the test stand is very cheap and the delivery time is fast.

Q: How is your workmanship?

A: Our 10 layer PCB line width and line spacing can be 3mil, the aperture can be 0.15mm, bag 0.23mm. Other special processes include:Thick Copper, Thick Gold(5U"), Gold Finger, Blind and Buried Hole, Countersink Hole, Semi-hole, Peelable Mask, Carbon Ink, Counter sink hole, Plated board edge, Press fit hole, Control depth hole, VIA in PAD, Non-conductive resin plug hole, Plating plug hole, Coil PCB, Super Mini PCB, Peelable Mask, Carbon Ink, Controlled Impedance PCB, etc.

Q: Can you make impedance control PCB? Can blind hole PCB be produced?

A: Yes, since the company was founded, we have produced numerous PCBs with different processes, including simple standard PCB, difficulty PCB, high-frequency PCB, impedance control PCB, BGA PCB, HDI PCB, thick copper PCB, etc. Experienced engineers and skilled technicians can ensure that your PCB can be delivered to you with high quality.

Q: What are your test methods

A: We provide: AOI, X-Ray(AU&NI), Two-dimension Measurement, Hole Copper Instrument, Controlled Impedance Test(Coupon test&Third Party Report), Metalloscope, Peeling Strength Tester, Solderability Test, Logic Contamination Test.

Q: How do you guarantee the quality of your products

A: The whole process quality monitoring, AOI and flying needle double test, to ensure product quality!

The 10 layer PCB controlled impedance circuit board means that the characteristic impedance of all the signal transmission circuits on the PCB conforms to the unified target specification, generally means that the characteristic impedance of all the signal transmission circuits is between 25 Ω and 70 Ω. If the characteristic impedances of the same 10 layer PCB interconnect are consistent everywhere, such PCB is of high quality.

Why the lower the impedance, the better? Because PCB should consider the electronic components, electrical conductivity, and signal transmission performance. On the other hand, in the production process of 10 layer PCB, copper deposition, tin plating (or chemical plating, or hot spray tin), connector soldering and other links as well as the materials used in this link must ensure the bottom resistivity, so as to ensure that the overall impedance of the circuit board is low enough to meet the product quality requirements, or the circuit board will not operate normally.

PCB Impedance Control Meaning and Influence Factor

With the increasing speed of PCB signal switching, PCB designers need to understand and control the impedance of PCB trace. Corresponding to the short signal transmission time and high clock rate of modern digital circuit, PCB trace is no longer a simple connection, but a transmission line.

The impedance value can be obtained by calculation in different ways.

In practice, it is necessary to control the trace impedance when the digital marginal velocity is higher than 1 ns or the analog frequency is higher than 300 MHz. One of the key parameters of PCB trace is its characteristic impedance (that is, the ratio of voltage and current when the wave is transmitted along the signal transmission line). The characteristic impedance of conductor on PCB is an important index of PCB design, especially in the PCB design of the high-frequency circuit, it must be considered whether the characteristic impedance of conductor is consistent with that required by device or signal and whether it matches. This involves two concepts: impedance control and impedance matching

What is Impedance Control in PCB

In order to improve the transmission rate, we must increase the frequency. If the circuit itself is etched, laminated thickness, wire width, and other different factors, it will cause the impedance value change and the signal distortion. Therefore, the impedance value of the conductor on the high-speed circuit board should be controlled within a certain range, which is called "impedance control".The impedance of PCB trace will be determined by its inductive and capacitive inductance, resistance and conductivity. The main factors that affect the impedance of PCB wiring are the width of copper wire, the thickness of copper wire, the dielectric constant of the medium, the thickness of the medium, the thickness of the pad, the path of ground wire, the wiring around the wiring, etc. The PCB impedance range is 25 to 120 ohms.

Characteristic impedance: in practice, the PCB transmission line is usually composed of one conductor trace, one or more reference layers and insulating materials. Traces and layers form the control impedance. PCB will often adopt a multi-layer structure, and the control impedance can also be constructed in various ways. However, regardless of the method used, the impedance value will be determined by its physical structure and the electronic characteristics of the insulating material:

- Width and thickness of the signal trace

- Height of core or pre-filled material on both sides of trace

- Trace and layer configuration

- Insulation constant of core and pre-filled material

The characteristic impedance is also called single line impedance. As the name implies, the impedance of a single wire between control elements is usually 40ohm-60ohm, with 50ohm being the most common.

Differential impedance: the resistance interference between two adjacent signal lines in the same layer. The impedance value is usually 80ohm-120ohm, 90ohm and 100ohm are the most common.

PCB transmission line and lamination

There are two main types of PCB transmission line: microstrip line and stripline line.Microstrip line

The microstrip line is a stripped wire, which refers to the transmission line with only one side of the reference plane, the top and side are exposed to the air (or coated layer), which is located on the surface of Er circuit board with insulation constant, with power supply or ground plane as reference.In the middle is the dielectric. If the dielectric constant, the width of the line and the distance from the ground plane of the dielectric are controllable, its characteristic impedance is controllable, and its accuracy will be within ± 5%.

Stripline line

The stripline is a copper strip placed between two conductive planes. If the thickness and width of the line, the dielectric constant of the medium, and the distance between the two grounding planes are all controllable, the characteristic impedance of the line is also controllable, and the accuracy is within 10%.Difference between microstrip line and stripline line

1. The transmission delay time of a unit length microstrip line is only dependent on the dielectric constant and independent of the width or spacing of the line.2. Because one side of the microstrip line is FR4 (or other dielectric) and the other side is air (low dielectric constant), the speed is very fast, which is conducive to the signal with high-speed requirements (such as differential line, usually high-speed signal, and strong anti-interference).

3. Both sides of the stripline have a power supply or bottom layer, so the impedance is easy to control, and the shielding is better, but the signal speed is slower.

4. Generally, under the same dielectric condition, the loss of microstrip is small (linewidth), and the loss of stripline is large (the line is thin, with vias).

Precautions in Impedance Control PCB laminated design

(1) warpageThe laminated design of PCB should keep symmetry, that is, the thickness of the media layer and copper laying thickness of each layer should be symmetrical up and down. For a six-layer board, it means that the media thickness and copper thickness of top-gnd and bottom-power are the same, and the media thickness and copper thickness of gnd-l2 and l3-power are the same. In this way, the warpage will not occur during lamination.

(2) The signal layer shall be closely coupled with the adjacent reference plane (i.e. the thickness of the medium between the signal layer and the adjacent copper coating shall be very small); the power copper coating and the ground copper coating shall be closely coupled.

(3)In the case of very high speed, extra layers can be added to isolate the signal layer, but it is not recommended to add more power layers to isolate, which may cause unnecessary noise interference.

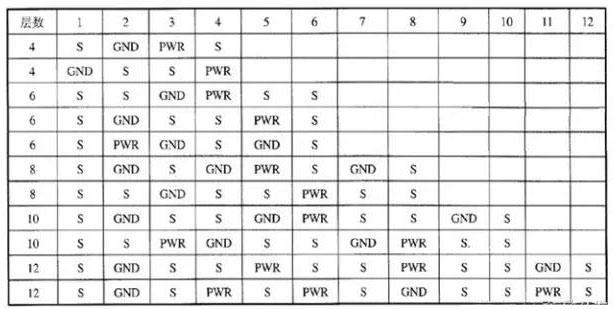

(4)The typical design layer distribution is shown in the table below:

(5)General principles of layer arrangement:

The lower part (the second layer) of the component surface is the ground plane, which provides the device shielding layer and the reference plane for the top layer wiring; all signal layers shall be adjacent to the ground plane as far as possible; two signal layers shall be avoided to be directly adjacent as far as possible; the main power supply shall be adjacent to the ground plane as far as possible; the lamination structure shall be considered.

Structure of Multilayer PCB

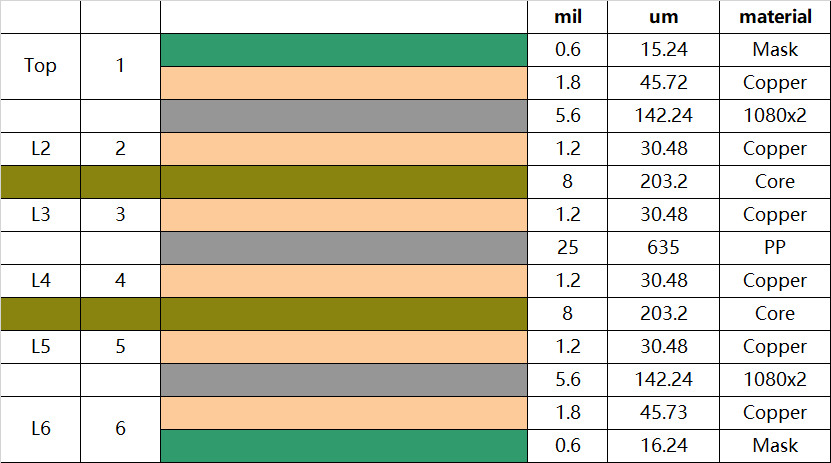

To control the impedance of PCB well, we should first understand the structure of PCB:Generally speaking, the multilayer printed circuit board is composed of core board and semi curing sheets, which is laminated with each other. The core board is a kind of hardboard with specific thickness and two layers of copper, which is the basic material of the printed circuit board. While the semi-cured sheet forms the so-called wetting layer, which plays the role of bonding the core plate. Although it also has a certain initial thickness, its thickness will change during the pressing process.

Generally, the two outermost dielectric layers of the multilayer circuit board are all infiltrating layers, and a separate copper foil layer is used as the outer copper foil. The original thickness specifications of outer copper foil and inner copper foil are generally 0.5oz, 1oz, 2oz (1oz is about 35um or 1.4mil), but after a series of surface treatments, the final thickness of the outer copper foil will increase by about 1oz. The inner copper foil is the copper-clad on both sides of the core plate. The difference between the final thickness and the original thickness is very small. However, due to the reason of etching, it will generally reduce several um.

The outermost layer of the multilayer PCB board is the solder mask layer, which is often called "green oil". Of course, it can also be yellow or other colors. Generally, the thickness of the solder mask layer is not easy to determine accurately. The area without copper foil on the surface is slightly thicker than the area with copper foil. However, due to the lack of the thickness of copper foil, the copper foil is still more prominent, which can be felt when we touch the surface of the PCB with our fingers.

When making PCB of a certain thickness, on the one hand, it is required to select the parameters of various materials reasonably, on the other hand, the final forming thickness of the semi-cured sheet will be smaller than the initial thickness.

Here is a typical 6-layer PCB laminated structure:

PCB Impedance Control Calculator

When we understand the structure of Multilayer PCB and master the required parameters, we can calculate the impedance through EDA software. You can use Allegro to calculate, or you can use polar's cits25, but here we recommend another tool, polarsi9000, which is a good tool for calculating characteristic impedance. Now many PCB factories are using this software.When calculating the characteristic impedance of inner layer signal, whether it is a differential line or single terminal line, you will find that there is only a small gap between the calculation result of polar si9000 and Allegro, which is related to some details, such as the shape of the cross-section of the conductor. But if it is to calculate the characteristic impedance of surface signal, I suggest you choose the coated model instead of the surface model, because this kind of model considers the existence of solder mask, so the result will be more accurate.

Because the thickness of the resistance layer is not easy to control, according to our many years of production experience, an approximate method can be used: subtract a specific value from the calculated results of the surface model, and it is recommended to subtract 8 ohms from the differential impedance and 2 ohms from the single end impedance. Contact us if you need more details on 10 Layer Impedance Control PCB. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Multilayer PCB Manufacturing Servics、10 Layer Impedance Control PCB Manufacturing. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Impedance Control PCB