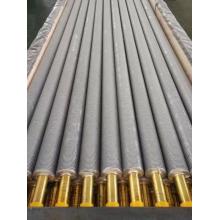

Aluminum L Type Finned Tube

| Unit Price: | 10~100 USD |

|---|---|

| Min. Order: | 100 Piece/Pieces |

| Packaging: | Wooden Case |

|---|---|

| Productivity: | 10000 Pieces Monthly |

| Brand: | Murphy |

| Transportation: | Ocean,Air,Land,Express,Others |

| Place of Origin: | China |

| Supply Ability: | 10000 Piece Monthly |

| Certificate: | ISO9001 |

| HS Code: | 7306400000 |

| Port: | Shanghai Port,Ningbo Port,Qingdao Port |

Click on the follow link to find out more information: https://www.murphyfinnedtube.com/l-ll-kl-kl-finned-tube/

Company Info

- Company Name: Murphy Thermal Energy Co., Ltd.

- Representative: Du Shuyang

- Product/Service: Fin Tube , High Frequency Finned Tube , Extruded Fin Tube , U Bend Tubes , Laser Welding Fin Tube , Finned Tube Coil

- Capital (Million US $): 5000000

- Year Established: 2019

- Total Annual Sales Volume (Million US $): Above US$100 Million

- Export Percentage: 61% - 70%

- Total Annual Purchase Volume (Million US $): US$50 Million - US$100 Million

- No. of Production Lines: 18

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: Fewer than 5 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: No. 2, Zhongsheng Road, Huangtang, Xuxiake Town, Jiangyin City

- Contact Person: Ms. Susanna Tang

- Tel: 86--13773013809

Premium Related Products

Other Products

Hot Products

types of aluminum profiles for windows 2014 hot sale China supplierAluminum sheets 8011 O4343/3003/4343 double sides cladded aluminum stripsHot selling productes with 8011 mill finish cleaning aluminum coil of 2.0mm8011 mill finish cleaning aluminum strips of 2.0mmchina low-price Aluminum strip ceiling 5052 alloy aluminum stripsaluminium coil 3004 aluminium coil for constructionsLeading aluminum manufacturer in China$1100 aluminum coils/aluminum edging strip/aluminum beltsCoated aluminum strip 1060 H24Leading manufacturer in China 7005 Aluminum sheet High quality low pricechina top quality 6063 T6 aluminum alloy plates and sheethot/cold rolled aluminum plate and sheetaluminum strips 3003 O H14 H18 H240.08-5.0mm thick 1060 aluminum plate5.0-400mm anodized 5083 aluminum alloy plate0.08-1.6mm thickness 5754 Aluminum coils/roll